Service hotline

+86 755-23775219

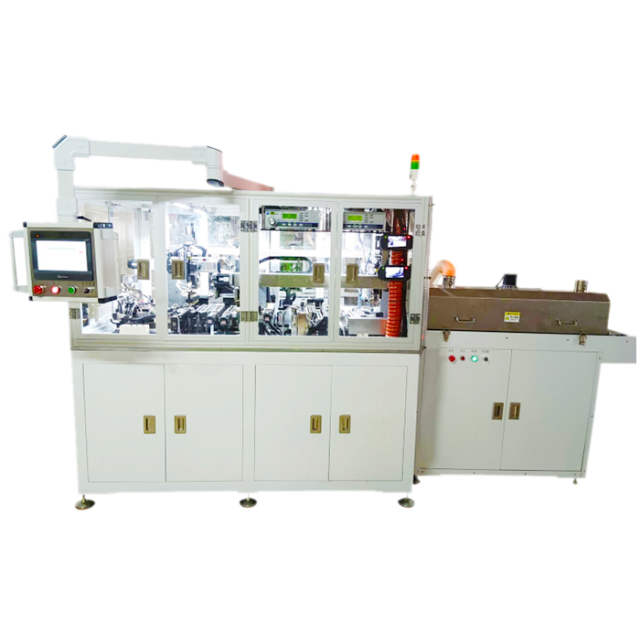

High efficiency, 10-axis winding at the same time, capacity up to 5.5K-6KPCS/H; Multi-axis linkage flexible winding, copper wire arrangement is more neat and beautiful; Automatic compensation of the whole line design, no damage to the lead wire, the lead wire is more close to the magnetic core; Flux automatic scraping design ensures that the magnetic core is coated evenly each time; High precision detection of tin surface, automatic tin adding function, accurate control of tin surface height; Customized high-end tin furnace, multi-point precise temperature control; The motor surface can be controlled by temperature and hot pressing, and the flatness and height of the product can be controlled; Imported spray dispensing anti-bubble entrapment, high-speed spot coating, fast spray function

please contact us with any questions and/or to request assistance, consultations or services.

Loading and unloading method: automatic loading of magnetic core vibration plate/finished product array on the conveyor belt;

Complete the process: automatically complete the feeding, winding, tin dipping, dispensing, drying;

Winding mode: multi-axis linkage winding;

Tail processing: fixed-point cutting/collection;

Applicable scope: NR20 ~ NR60 series inductor core;

Applicable wire diameter:0.04~0.3mm;

Number of spools: 10 spools simultaneously;

Production efficiency: 5K-6KPCS/H;

Working environment: -5 ℃ ~ 50 ℃, no corrosive gas, dust and other harsh environment;

Machine size: L1900 X W1350 X H1990mm;

Oven size: L1550 X W380 X H1380mm;

Power supply: single-phase AC220V, 50 HZ;

Air supply: 0.6 ~ 0.7 MPa;

Power: 6.8KW;

Weight of complete machine: about 850 KG.