Service hotline

+86 755-23775219

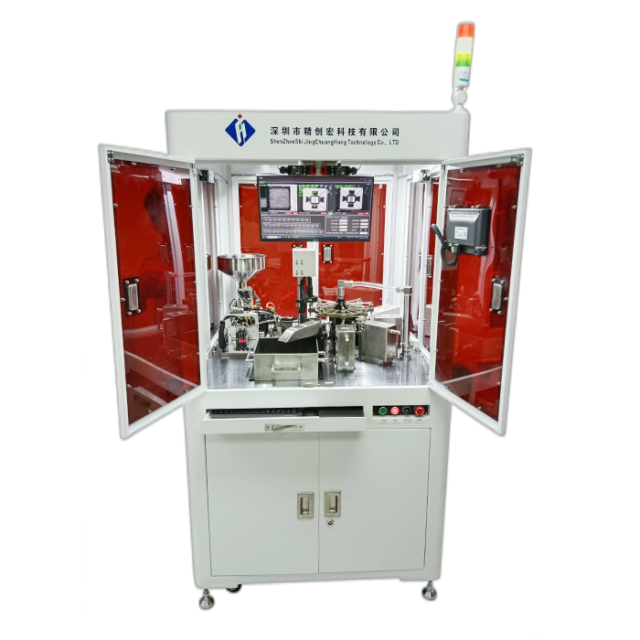

High accuracy, product static state drawing, clear imaging, accurate definition; High recognition rate, can identify invisible slight cracks, damage, color difference, etc; High efficiency, capacity 12KPCS/H; Patented five-sided imaging technology, introducing the number of cameras, easy debugging, simple operation; The self-developed defect analysis algorithm is efficient, fast and accurate. Damage, hidden crack, dirt, poor size, poor air hole, etc.; can be automatically classified and collected according to the bad definition; High stability of the equipment, new design with screening vibration plate, high-speed standard parts selection.

please contact us with any questions and/or to request assistance, consultations or services.

Loading and unloading mode: automatic loading of inductive vibration plate/automatic sorting and collection of material box;

Complete the process: automatically complete the feeding, six-sided appearance inspection, classification and collection;

Applicable scope: NR20 ~ NR60 series inductor/capacitor/resistor/LED, etc. Customizable upon request:

Production efficiency: 12KPCS/H;

Working environment: -5 ℃ ~ 50 ℃, no corrosive gas,Fly dust and other harsh environments;

Machine size: L1000 X W1000 X H1800mm;

Power supply: single-phase AC220V, 50 HZ;

Air supply: 0.6 ~ 0.7 MPa;

Power size: 2.0 KW;

Weight of complete machine: about 600 KG.